Pune, a bustling hub of industrial activity, has seen a significant transformation in its manufacturing landscape, largely thanks to advancements in technology. One such technological marvel is the CNC drilling machine, a game-changer for precision engineering and manufacturing. At the forefront of this revolution is Yantra Design, a company renowned for its expertise in CNC drilling and commitment to excellence.

Are you in search of a CNC drilling machine in Pune? Look no further than Yantra Design, where precision meets excellence.

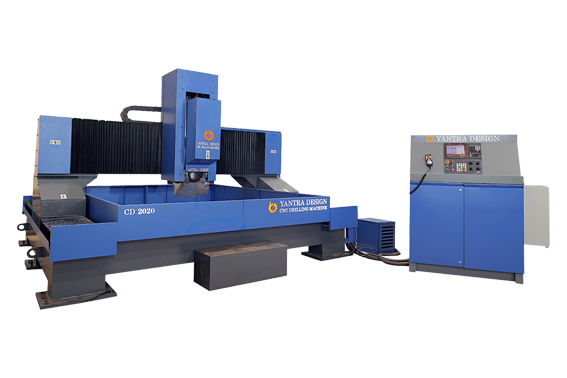

Yantra Design has launched some advanced CNC Drilling Machines in Pune.

If you find it difficult to understand. You can also connect with us directly. Our consultant engineers will guide you about the best suitable CNC Drilling Machine available in Pune.

Let's understand from the basics.

A CNC (Computer Numerical Control) drilling machine is an automated piece of equipment used to drill holes in various materials with high precision and consistency. Unlike traditional drilling machines, CNC drilling machines are controlled by computer software, which ensures accuracy and repeatability.

CNC drilling involves a series of programmed instructions that guide the machine's movements and operations. The process typically includes:

CNC drilling machines offer several benefits that make them indispensable in modern manufacturing:

CNC drilling machines can achieve micron-level precision, which is crucial for industries that demand high-quality standards.

Automation reduces human error and allows for continuous operation, significantly boosting productivity.

Although the initial investment is higher, CNC drilling machines reduce labor costs and material waste, leading to long-term savings.

In Pune, manufacturing industries utilize CNC drilling machines for a wide range of applications across various sectors, including:

Used for drilling engine components, chassis parts, and other critical elements.

Essential for creating precise holes in aircraft components, ensuring safety and performance.

Yantra Design, a leader in precision engineering, has built a reputation for excellence in CNC drilling. With years of experience and a team of skilled professionals, they offer unparalleled services in Pune.

Founded with a vision to innovate, Yantra Design has grown to become a trusted name in the industry. Their commitment to quality and customer satisfaction has been the cornerstone of their success.

Yantra Design specializes in CNC drilling, providing customized solutions to meet the unique needs of their clients. Their expertise spans various industries, ensuring high-quality results every time.

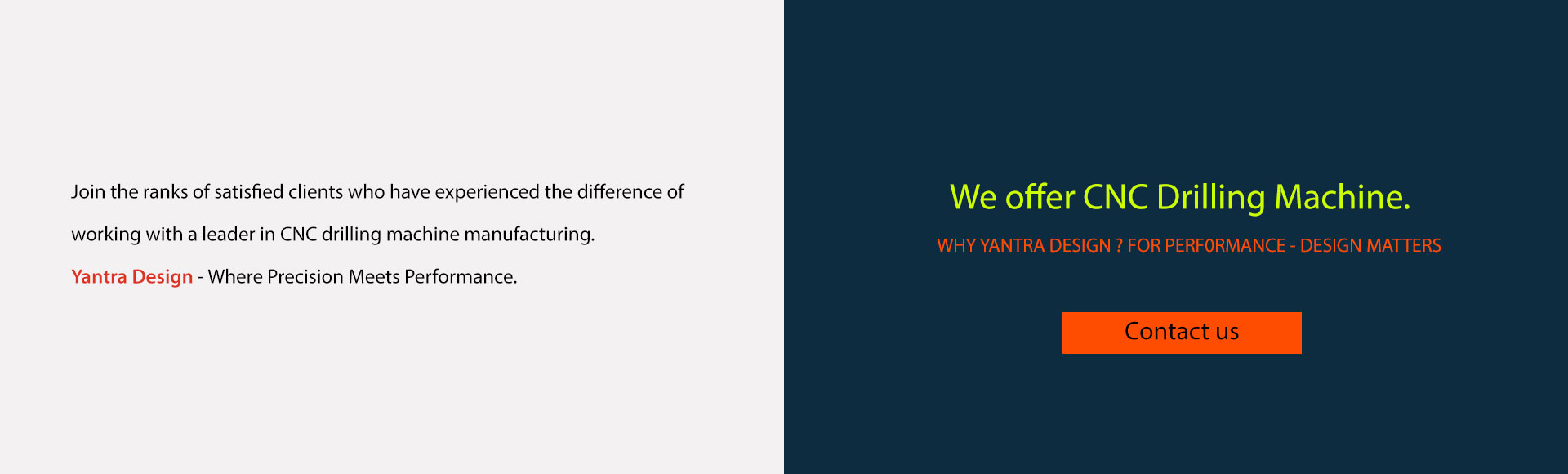

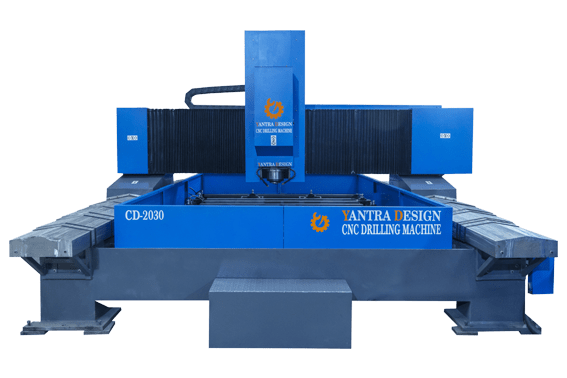

Yantra Design boasts state-of-the-art facilities equipped with the latest technology. Their infrastructure includes advanced CNC drilling machines, ensuring precision and efficiency in every project.

One of the key strengths of Yantra Design is their ability to offer customized solutions. They work closely with clients to understand their requirements and deliver tailored results that exceed expectations.

From prototyping to full-scale production, Yantra Design provides flexible services that adapt to the changing needs of their clients.

Whether it’s a small batch or large-scale production, Yantra Design’s flexible approach ensures timely and cost-effective solutions.

Quality is paramount at Yantra Design. They adhere to strict quality control processes to ensure that every product meets the highest standards.

From raw material inspection to final product testing, Yantra Design implements rigorous quality checks at every stage of production.

Yantra Design is certified to meet international quality standards, providing clients with the assurance of reliability and excellence.

Yantra Design is committed to sustainable manufacturing practices. They implement eco-friendly processes to minimize their environmental footprint.

Utilizing energy-efficient machines and recycling waste materials are just a few ways Yantra Design promotes sustainability.

Initiatives like reducing carbon emissions and using renewable energy sources highlight Yantra Design’s dedication to environmental responsibility.

Yantra Design has a demonstrated history of success, with numerous case studies highlighting their expertise in CNC drilling machines at Pune location.

From automotive components to aerospace parts, Yantra Design has successfully completed projects for various industries.

Clients are happy with Yantra Design for their quality, reliability, and exceptional service.

The future of CNC drilling in Pune looks promising, with emerging technologies set to enhance capabilities further.

Advancements in automation, AI, and IoT are poised to revolutionize CNC drilling, making it more efficient and precise.

Yantra Design aims to stay at the forefront of these innovations, continually improving their services to meet the evolving needs of their clients.

Yantra Design stands out for several reasons, making them the go-to choice for CNC drilling in Pune.

Their combination of advanced technology, skilled professionals, and customer-centric approach sets them apart from the competition.

Yantra Design prioritizes customer satisfaction, offering personalized services that ensure clients' needs are met with utmost precision.

CNC drilling machines have revolutionized the manufacturing industry, providing unparalleled precision and efficiency. Yantra Design, with its expertise and state-of-the-art facilities, is leading this transformation in Pune. Whether you’re in the automotive, aerospace, or any other industry, Yantra Design is your trusted partner for all your CNC drilling needs.